Avoiding Robot Collisions: Cobot & Industrial Robot Workspace Safety – Understanding the Critical Differences

Introduction: The Safety Imperative in Robot Integration

The drive towards automation in manufacturing hinges critically on safety. As factories integrate both traditional industrial robots and newer collaborative robots (cobots), understanding their fundamental safety differences isn't just technical – it's paramount for preventing accidents, optimizing workflows, and ensuring regulatory compliance. While both aim to boost productivity, their approaches to workspace safety and collision avoidance diverge significantly. This article dissects these critical distinctions to guide safer implementation.

Core Safety Philosophies: Separation vs Cooperation

- Industrial Robots: Safety Through Isolation & Guarding

- Design Principle: Built for raw power, speed, precision, and repeatability in highly structured, predictable tasks. Their primary safety strategy is physical separation from humans.

- Key Safety Features:

- Safety Fences & Hard Guarding: Physical barriers (cages, light curtains, safety mats, interlocks) are mandatory to create a strictly defined robot operating zone. Access halts the robot immediately (e.g., via safety-rated monitored stop).

- High-Speed Operation: Capable of very fast movements, making unintended human contact potentially catastrophic. Isolation is non-negotiable during operation.

- Limited Inherent Sensing: Traditional industrial arms lack sophisticated built-in force/torque sensing or advanced proximity detection for safe human interaction.

- Safety Standards Focus: Primarily governed by ISO 10218-1 & -2 (Robots and Robot Systems). These standards emphasize risk assessment and implementing protective measures (like guarding) to mitigate hazards identified during the assessment.

- Collaborative Robots (Cobots): Safety Through Inherent Design & Control

- Design Principle: Engineered from the ground up for shared workspaces where direct human-robot interaction (HRI) is not just possible but intended. Safety is embedded in their core.

- Key Safety Features (Defined by ISO/TS 15066):

- Power & Force Limiting (PFL): The cornerstone of cobot safety. Robots incorporate joint torque sensors and sophisticated control algorithms to limit impact forces and pressures below biologically defined thresholds (specified in ISO/TS 15066 Annex A) upon contact. This prevents injury.

- Inherently Safe Design: Rounded edges, minimized pinch points, lightweight materials, and smooth surfaces reduce injury severity if contact occurs.

- Speed & Separation Monitoring: Cobots dynamically monitor the distance to nearby humans using vision systems, lasers, or area scanners. They automatically slow down as a human approaches and stop if a predefined safety distance is breached, resuming only when the area is clear.

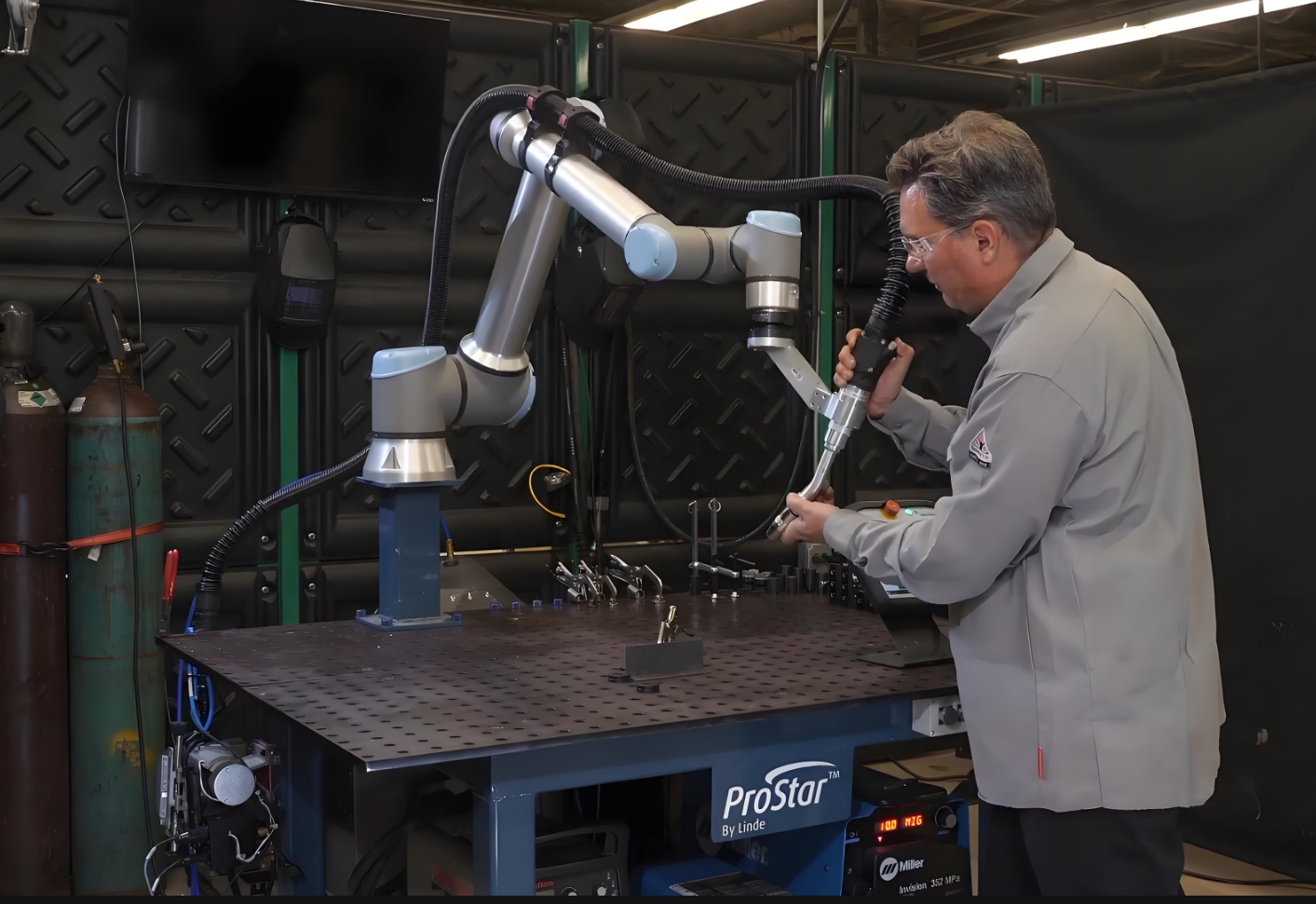

- Hand Guiding: Allows an operator to physically teach the robot a path by moving its arm directly, with the robot detecting the guiding force and complying safely.

- Safety-Rated Monitored Stop: Stops motion safely upon detecting a human entering the collaborative workspace.

- Safety Standards Focus: Governed by ISO 10218 (for the robot system) and specifically ISO/TS 15066 (Collaborative Robots). TS 15066 provides the crucial technical specifications for the four collaborative operation modes (PFL, Speed & Sep., Hand Guid., Monitored Stop) and defines the maximum permissible transient and quasi-static contact forces/pressures on different body regions.

The Critical Differences in Practice: Workspace Safety & Collision Avoidance

- Workspace Layout & Footprint:

- Industrial: Requires significant dedicated floor space for the robot cell plus the safety perimeter (guarding). Layout is rigid. Collision avoidance is primarily achieved by keeping humans out.

- Cobot: Designed for flexible, compact integration directly on the shop floor near human workers. The workspace is dynamic and shared. Collision avoidance relies on sensors, speed control, and PFL to manage safe interaction within the shared space. Space savings are substantial.

- Risk Assessment Complexity:

- Industrial: Focuses on ensuring the integrity of the safety perimeter (guarding, interlocks) and emergency stops. Hazards are primarily within the cell.

- Cobot: Risk assessment is significantly more complex. It requires a meticulous analysis of all potential human-robot interaction points, the nature of tasks, the tools/parts carried (which drastically alter collision dynamics), and verification that contact forces under all foreseeable conditions remain below ISO/TS 15066 thresholds. Tooling and workpiece safety is paramount for cobots.

- Collision Consequences & Mitigation:

- Industrial: A collision between an industrial robot and a human is highly likely to cause severe injury or death due to mass and speed. Mitigation is entirely preventative (keep humans out). Recovery requires restarting the cell.

- Cobot: A collision is designed to be a manageable event. PFL ensures contact forces are non-injurious (though potentially startling). The robot stops immediately upon significant contact detection. Recovery often involves simply moving the robot arm slightly (manually or via hand guiding) and restarting – minimal downtime. Mitigation focuses on safe contact characteristics.

- Integration Flexibility & Application Scope:

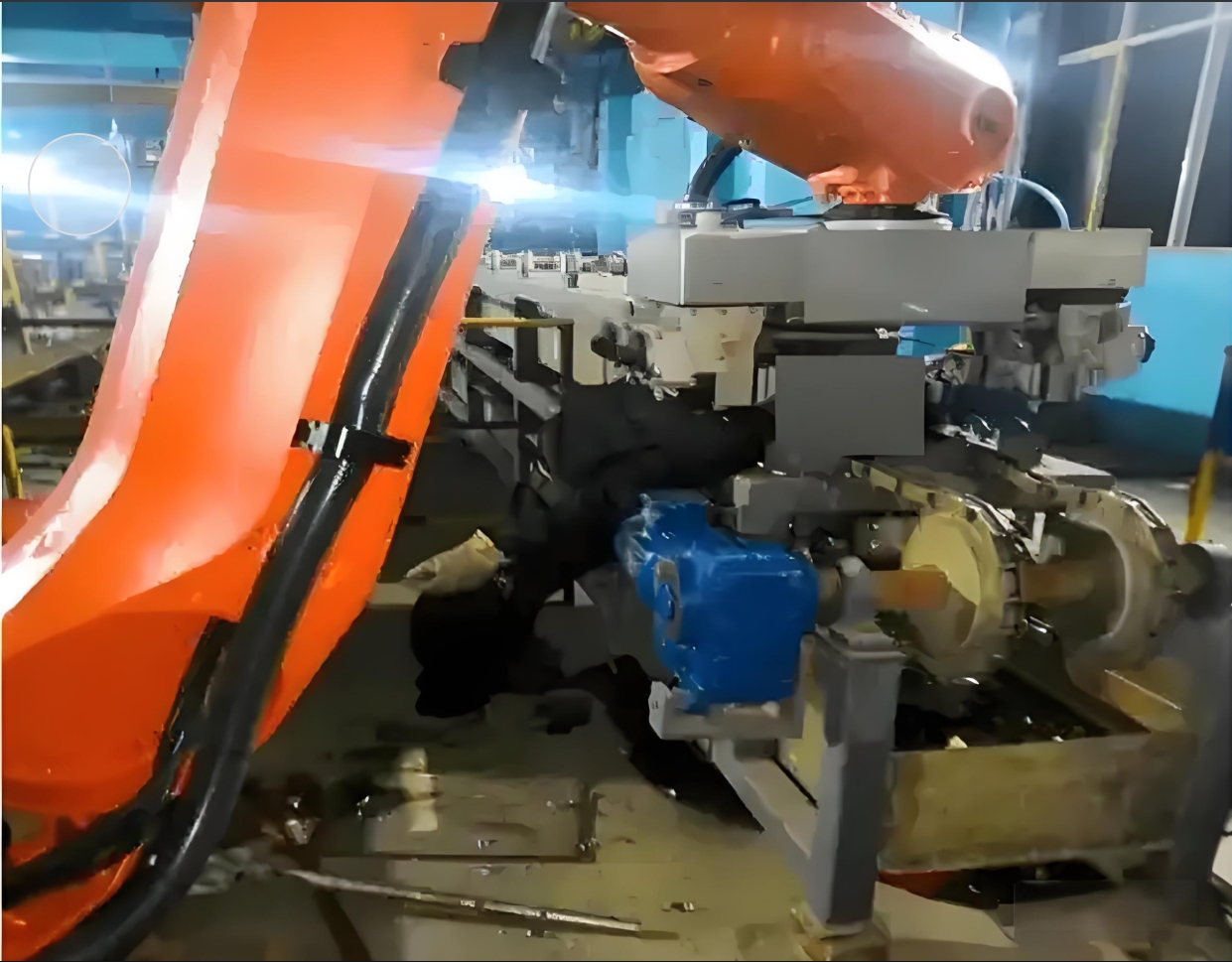

- Industrial: Ideal for high-volume, high-speed, heavy-payload tasks in fully automated, isolated cells (e.g., welding, painting, heavy palletizing).

- Cobot: Excels in tasks requiring flexibility, frequent changeovers, and direct human collaboration (e.g., machine tending, assembly, inspection, packaging, finishing). Enables human-robot teamwork where humans handle dexterity/cognition and cobots handle ergonomically taxing or repetitive motions.

- Safety System Costs:

- Industrial: Significant upfront cost for robust physical guarding (fencing, light curtains, safety controllers, installation). Perimeter is fixed.

- Cobot: Higher unit cost for the robot itself (due to embedded safety tech), but drastically reduced or eliminated costs for extensive fixed guarding. Safety systems (sensors, software) are often more adaptable if the cell layout changes.

Beyond the Robot: The Shared Safety Ecosystem

Regardless of robot type, comprehensive workspace safety relies on a holistic approach:

- Thorough Risk Assessment (ISO 12100): Mandatory first step for any robot integration. Identify hazards, estimate risks, implement controls. For cobots, this must include detailed PFL verification using the methodology in ISO/TS 15066.

- Operator Training: Humans working near robots must understand their operation, limitations, safety procedures, and emergency responses. Training differs significantly between isolated industrial cells and collaborative workspaces.

- Procedural Safeguards: Clear work instructions, lockout/tagout (LOTO) procedures for maintenance, and defined zones for interaction.

- Ongoing Maintenance & Validation: Regular checks of safety functions (e.g., testing E-Stops, verifying sensor functionality, ensuring guarding integrity) are critical. Cobot PFL performance must be re-verified if end-effectors or payloads change significantly.

- Safety Controllers & PLCs: Both systems rely on safety-rated controllers (PLd/PLe per ISO 13849-1) to process safety signals (e.g., door interlocks, E-Stops, scanner zones, cobot safety inputs/outputs) and execute safe stops.

Choosing the Right Tool: Safety is Paramount

The choice between an industrial robot and a cobot should never be based solely on cost or trend. Safety requirements dictated by the application are the primary driver:

- Choose Industrial Robots When: Tasks require very high speed, heavy payloads, extreme precision over large workspaces, or involve hazardous processes (sparks, chemicals). Human presence during operation is unnecessary or undesirable. Safety is achieved by exclusion.

- Choose Cobots When: Tasks benefit from close human-robot interaction, require frequent reprogramming/flexibility, involve lower payloads/speeds, or aim to improve human ergonomics by offloading repetitive tasks. Safety is achieved by controlled coexistence.

The Future: Blurring Lines and Enhanced Safety

The boundaries are evolving. Traditional industrial robots are increasingly equipped with advanced collision avoidance systems (vision, LiDAR) and even PFL capabilities for specific applications, allowing for more flexible guarding solutions or limited collaborative scenarios (sometimes called "industrial cobots" or "cobot-like" features). Conversely, cobots continue to gain payload and reach, expanding their application scope. Regardless of the label, adherence to the relevant safety standards (ISO 10218, ISO/TS 15066) and rigorous risk assessment remain the bedrock of robotic workspace safety and effective collision prevention.

Conclusion: Safety by Design Defines the Difference

The fundamental divergence between industrial robots

Collaborative,Welding,Robots,,Cobot,Welding,Solutions, ,Automated,Welding,Cobots,,Safe,Welding,Robotics,

BLOG

previous page