DOBOT Robotics: A Comprehensive Analysis of a Leading Cobot Innovator & Global Challenger

Introduction: The Cobot Revolution and DOBOT's Ascent

The collaborative robot (cobot) market is exploding, driven by the need for flexible automation that works safely alongside humans. Among the key players challenging established giants is DOBOT Robotics (越疆科技), a Shenzhen-based innovator rapidly gaining global recognition. Founded in 2015, DOBOT has carved a significant niche by focusing on user-friendly cobot solutions, competitive pricing, and diverse application adaptability. This analysis provides a deep dive into the DOBOT cobot brand, examining its technology, market position, strengths, challenges, and future trajectory – essential reading for anyone exploring industrial automation solutions or collaborative robotics manufacturers.

Company Profile: From Startup to Global Cobot Contender

- Origin & Mission: Founded with the vision of making robotics accessible, DOBOT emerged from the vibrant Chinese tech ecosystem. Their mission centers on empowering businesses of all sizes with easy-to-use automation, enhancing productivity and safety. Key search terms: DOBOT Robotics history, cobot company Shenzhen, affordable automation solutions.

- Global Footprint: While headquartered in China, DOBOT has aggressively expanded internationally. They boast subsidiaries and a robust distributor network across Europe, North America, Southeast Asia, Japan, and South Korea, demonstrating their commitment to the global cobot market. Key search terms: DOBOT distributors, cobot suppliers worldwide, international robotics companies.

- R&D Prowess: DOBOT invests heavily in robotics R&D, holding numerous patents in robot control, drive systems, and human-robot interaction. Their focus remains on core technologies like high-precision motion control, force sensing, and intuitive cobot programming interfaces.

DOBOT Cobot Portfolio: Designed for Versatility and Ease

DOBOT offers a comprehensive range of cobots catering to varied payloads and applications:

- CR Series (Core Industrial): The flagship line designed for industrial automation tasks. Known for reliability, high repeatability (±0.02mm), and extensive payload options.

- Models: CR3 (3kg), CR5 (5kg), CR10 (10kg), CR16 (16kg), CR20 (20kg).

- Features: High payload-to-weight ratio, IP54 protection (select models), embedded vision options (CRVison), tool flange options (ISO 9409-1-50-4-M6 & -63-4-M6), collision detection, drag teaching, simple programming (DOBOTStudio software). Key search terms: CR series cobots, industrial cobot payloads, high-precision robots, cobot with embedded vision.

- Nova Series (All-Rounder): Positioned as versatile cobots balancing performance and value. Slightly lower precision (±0.05mm) than CR but highly capable for many tasks.

- Models: Nova 5 (5kg).

- Features: Excellent cost-performance ratio, compact design, easy integration, intuitive graphical programming. Key search terms: Nova series cobot, value collaborative robot, easy-to-integrate automation.

- Magician Series (Education & Light Industry): Pioneering DOBOT's early success, focused on educational robotics, R&D prototyping, and light-duty applications.

- Models: Magician Lite, Magician.

- Features: Multi-functional tool heads (3D printing, laser engraving, gripper), STEM education focus, desktop cobot, programming learning platform (Blockly, Python). Key search terms: educational cobot, STEM robotics kit, desktop robot arm, DOBOT Magician.

Core Technological Strengths & Innovations

- Precision & Performance: DOBOT cobots, especially the CR series, deliver high repeatability positioning crucial for assembly automation, precision dispensing, and machine tending. Their efficient drive systems contribute to a high payload-to-weight ratio.

- Safety First: All DOBOT industrial cobots comply with stringent ISO 10218-1 and ISO/TS 15066 safety standards for collaborative operation. Features include collision detection, speed and separation monitoring, and power and force limiting (PFL). Key search terms: cobot safety standards, ISO/TS 15066 compliant, collaborative robot safety features.

- Intuitive User Experience: A major selling point is ease of use:

- DOBOTStudio Software: Features graphical block programming, script programming (Python/Lua), and app-based control, significantly lowering the barrier for cobot programming and rapid deployment.

- Drag Teaching: Allows operators to physically guide the robot arm to program paths effortlessly.

- Rich Ecosystem: Supports various EOAT (End-of-Arm Tooling) – electric, pneumatic, vacuum grippers – and integrates with machine vision systems (like CRVison) and PLC communication protocols (Modbus TCP, Ethernet/IP). Key search terms: easy cobot programming, drag and teach robots, cobot software DOBOTStudio, cobot end effectors, cobot machine vision integration.

- Embedded Vision (CRVison): Integrating vision directly into the robot controller (CR series) simplifies vision-guided applications like bin picking, precision assembly, and inspection, reducing complexity and cost compared to external systems. Key search terms: embedded vision cobot, vision guided robotics, DOBOT CRVison.

Target Markets & Application Verticals

DOBOT cobots excel in diverse sectors, emphasizing flexibility:

- Manufacturing: Core market for automated assembly, machine loading/unloading (CNC tending), material handling, packaging automation, screw driving, quality inspection, gluing and dispensing. Key search terms: factory automation cobots, cobot machine tending, automated assembly solutions.

- Automotive: Used in electronics assembly, component testing, light assembly tasks, and internal logistics within the supply chain.

- 3C Industry (Consumer Electronics): High demand for precision assembly, testing, small parts handling, and PCB processing where DOBOT's accuracy shines.

- Food & Beverage: Handling, packaging, palletizing (with higher payload models), adhering to hygiene standards (IP54 options available). Key search terms: cobot food packaging, palletizing robot.

- Education & Research: The Magician series is widely adopted in universities, vocational schools, and corporate R&D labs for teaching robotics programming, automation concepts, and prototyping new applications. Key search terms: educational robot arm, robotics lab equipment, STEM education robot.

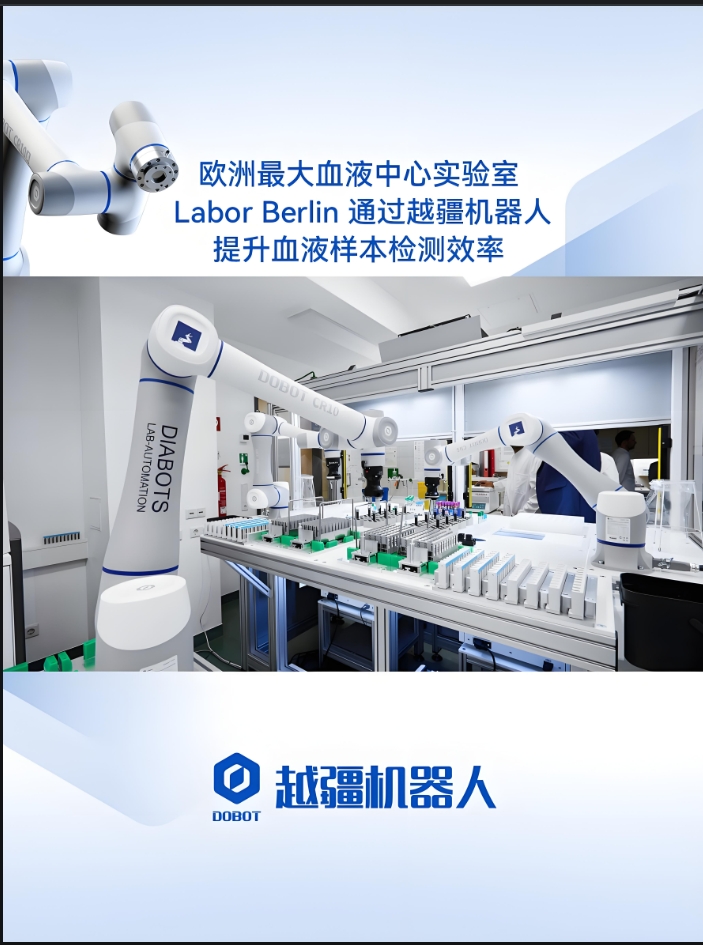

- Emerging Applications: Exploring roles in healthcare (lab automation, sterilization support), retail, and service industries. Key search terms: cobots in healthcare, service robotics applications.

Market Position & Competitive Landscape

- Value Proposition: DOBOT's primary strength is offering feature-rich cobots at a significantly lower price point than leading Western competitors like Universal Robots (UR) or Techman Robot. This makes collaborative robot automation accessible to SMEs (Small and Medium Enterprises) and cost-sensitive industries. Key search terms: affordable collaborative robots, cobot price comparison, automation for SMEs.

- Global Challenger: DOBOT is firmly positioned as a major Chinese cobot manufacturer challenging the dominance of UR. They compete aggressively on price while closing the gap in performance and features. Other competitors include AUBO, Elite, Han's Robot, and the established giants (ABB Yumi, FANUC CRX, KUKA LBR iiwa).

- Brand Perception: Known for good value for money and ease of use. Historically, perception lagged in absolute top-tier precision and global service/support depth compared to UR, but this is rapidly improving with investment and experience. Key search terms: DOBOT vs Universal Robots, cobot reviews, cobot reliability.

Challenges and Considerations

- Service & Support: While expanding, building a truly global, deeply skilled service and support network to rival the longest-established players takes significant time and investment. Local support quality can vary.

- Premium Perception: Overcoming the perception (fair or not) that lower price equates to lower quality or performance in some high-end market segments remains a hurdle.

- Software Ecosystem: While DOBOTStudio is capable, UR's URCap ecosystem is currently broader and more mature, offering a wider variety of pre-developed application solutions.

- Geopolitics: Trade tensions and supply chain diversification trends can impact sourcing and market access strategies for any Chinese manufacturer.

Future Outlook & Strategic Direction

- AI & Advanced Sensing: Integrating artificial intelligence (AI) and more sophisticated sensors (force/torque, advanced vision) for smarter, more adaptive applications like predictive maintenance and complex quality control.

- Mobile Cobots (AMRs): Combining cobot arms with Autonomous Mobile Robots (AMRs) to create highly flexible intralogistics solutions and on-demand manufacturing cells. Key search terms: mobile manipulator cobot, AMR with robot arm.

- Cloud & IIoT: Enhancing connectivity, data analytics, and remote monitoring capabilities through cloud robotics platforms and Industrial Internet of Things (IIoT) integration for smarter factories. Key search terms: IIoT cobots, cloud-based robot control.

- Vertical-Specific Solutions: Developing more tailored application packages and cobot cells for specific high-demand industries like electronics manufacturing or pharmaceuticals.

- Sustainability Focus: Emphasizing energy-efficient cobot designs and applications contributing to sustainable manufacturing.

Conclusion: A Force Reshaping Accessible Automation

DOBOT Robotics has rapidly evolved from an ambitious startup into a formidable global force in the collaborative robotics industry. By prioritizing user-friendliness, delivering robust performance at a competitive price point, and fostering a growing global presence, DOBOT has successfully democratized access to advanced automation, particularly for SMEs. Their comprehensive portfolio, spanning industrial workhorses (CR) to educational pioneers (Magician), coupled with continuous innovation in embedded vision, intuitive software, and safety, positions them strongly for sustained growth. While challenges in global service maturity and ecosystem breadth persist, DOBOT's aggressive R&D and expansion strategies signal their commitment to being a long-term leader. For businesses seeking cost-effective, flexible, and easy-to-deploy cobot solutions across diverse manufacturing automation, logistics, and educational scenarios, DOBOT presents a compelling and increasingly sophisticated choice, reshaping expectations in the global industrial robotics market. Key search terms: future of cobots, benefits of collaborative robots, DOBOT cobot advantages, implementing factory automation.

Cobot,,Dobot,,Cobotwelder,,Weldingcobot,

BLOG