Collaborative Robots in MIG Welding: A Paradigm Shift in Industrial Automation

The integration of collaborative robots (cobots) into industrial welding processes has revolutionized traditional manufacturing, particularly in Metal Inert Gas (MIG) welding. As industries face challenges such as labor shortages, rising costs, and demand for precision, cobots offer a transformative solution. This article explores the key advantages of deploying collaborative robots in MIG welding, supported by technical insights and industry applications.

1. Addressing Labor Shortages and Skill Gaps

The global shortage of skilled welders has become a critical bottleneck for industries. In China, for instance, the average annual salary for welders in eastern regions reached 90,000–110,000 RMB in 2021, significantly higher than the manufacturing average, yet younger generations increasingly avoid this physically demanding profession. Collaborative robots fill this gap by automating repetitive MIG welding tasks, allowing human workers to focus on higher-value roles such as process supervision or complex repairs. Companies like DeAngelo Marine Exhaust have reported a 10-fold increase in productivity after adopting cobot-based MIG systems, demonstrating their capacity to mitigate workforce challenges.

2. Enhanced Precision and Consistency

MIG welding demands high precision to ensure strong, aesthetically pleasing seams. Collaborative robots excel in this domain due to advanced motion control algorithms and real-time error correction technologies. For example:

- Repeatability: Cobots like the Elfin-Pro series achieve repeat positioning accuracy of ±0.02 mm, ensuring consistent weld paths even in high-speed operations.

- Adaptive Control: Integrated systems such as laser vision tracking and arc correction automatically adjust the welding torch’s position to maintain alignment with the weld seam, reducing deviations caused by thermal distortion or workpiece irregularities68.

- Force Sensitivity: Force-controlled cobots, such as those from Universal Robots (UR), apply precise pressure (e.g., ±3N force control) to avoid under- or over-welding, critical for thin materials or complex geometries.

These capabilities ensure uniform weld quality, reducing rework rates and material waste.

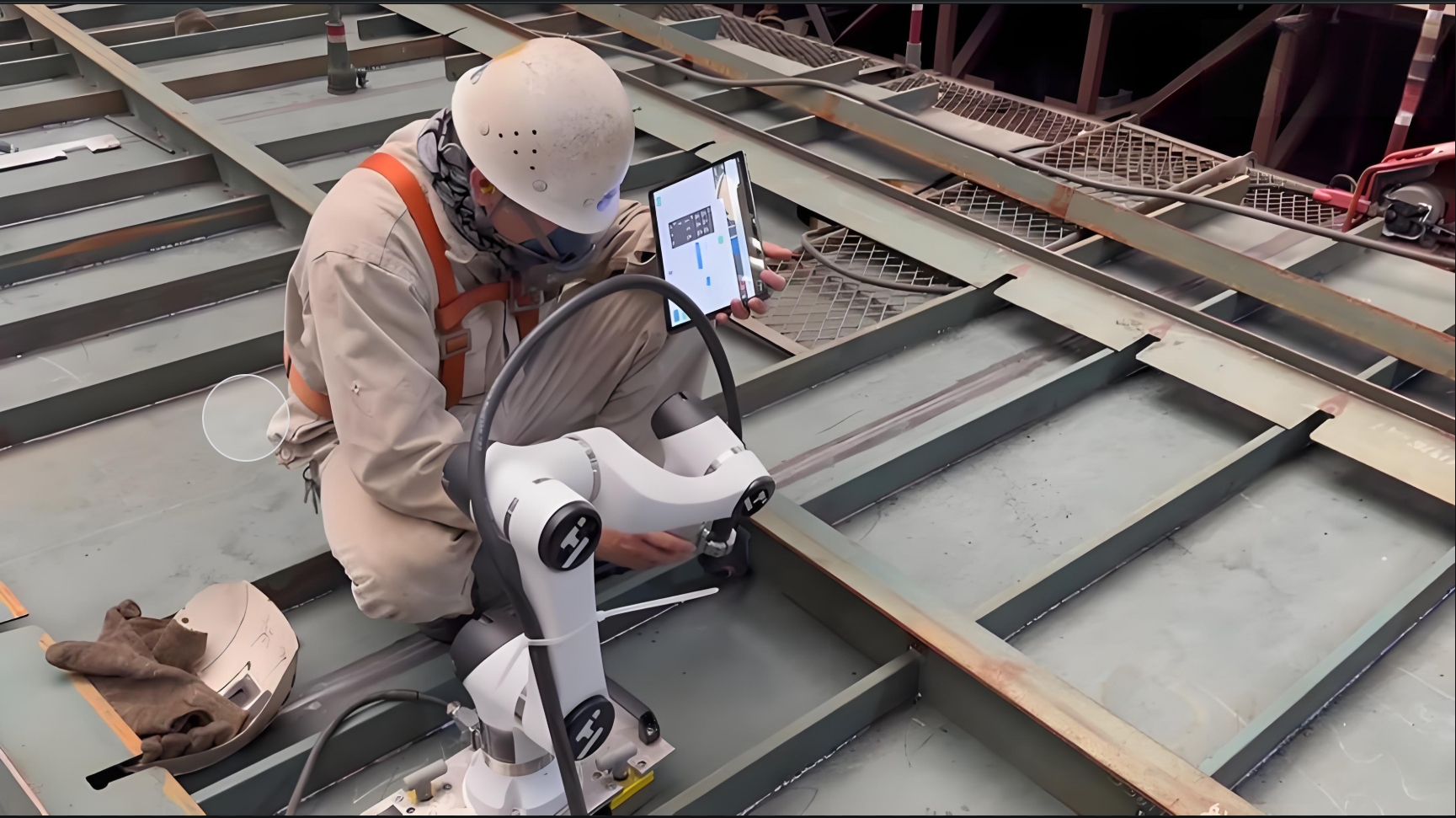

3. Flexibility and Ease of Deployment

Unlike traditional industrial robots, cobots are designed for rapid integration and adaptability:

- Drag-and-Teach Programming: Systems like the Elfin-Pro allow operators to physically guide the robot’s arm to define welding paths, eliminating the need for complex coding. This "zero threshold" approach democratizes automation, enabling even novice users to set up tasks within minutes.

- Portability: Modular designs, such as portable welding stations with magnetic bases, enable cobots to be relocated across workshops or outdoor sites, supported by 50-meter cables for extended reach.

- Compatibility: Cobots seamlessly integrate with mainstream welding equipment (e.g., Fronius, Panasonic) and support diverse welding trajectories (circular, linear, V-shaped), making them suitable for applications ranging from automotive parts to shipbuilding.

4. Improved Safety in Human-Robot Collaboration

Safety is paramount in welding environments, where hazards include sparks, fumes, and high-voltage equipment. Cobots address these risks through:

- Collision Detection: Sensors and electromagnetic brakes halt motion upon contact, preventing accidents during close human interaction.

- Reduced Exposure: Automated systems minimize workers’ proximity to welding arcs, lowering health risks from prolonged fume inhalation.

- Emergency Stop Mechanisms: Advanced safety protocols ensure immediate shutdown during power failures or emergencies, enhancing workplace safety.

5. Cost Efficiency and Rapid ROI

The economic benefits of cobots are compelling:

- Lower Initial Investment: Cobots are typically 30–50% cheaper than traditional industrial robots, with simplified installation reducing setup costs.

- Reduced Downtime: Quick reprogramming and tool-switching capabilities allow cobots to adapt to new tasks within hours, unlike fixed automation systems requiring days of reconfiguration.

- ROI Acceleration: Case studies, such as T&W Stamping’s UR5-based welding cell, demonstrate full ROI within 4 months through zero-defect production and doubled output.

6. Technological Synergy: MIG Welding and Cobot Innovations

The synergy between MIG welding and cobot advancements drives further optimization:

- Arc Stability: MIG welding with cobots benefits from stable argon gas shielding, minimizing spatter and ensuring smooth, high-strength welds5.

- Heat Management: Cobots’ precise control reduces heat input, critical for thin materials, and preserves the integrity of coated metals (e.g., galvanized steel).

- AI-Driven Optimization: Emerging solutions integrate AI models for dynamic error compensation and predictive maintenance, further enhancing weld quality and equipment longevity.

Future Outlook

The future of cobot-driven MIG welding lies in intelligent, interconnected systems. Advances in 3D vision, edge computing, and AI will enable real-time adaptive welding for non-standardized components, a persistent challenge in sectors like shipbuilding and construction. Chinese manufacturers, such as DJI’s subsidiary Dajiang, are leading the charge, with cobot adoption rates projected to grow at a 30% CAGR through 2026.

Conclusion

Collaborative robots are redefining MIG welding by merging precision, flexibility, and affordability. As industries transition toward smart manufacturing, cobots will remain pivotal in addressing labor constraints, elevating product quality, and driving sustainable growth. For businesses seeking competitive advantage, investing in cobot-based welding solutions is not just an option—it is an imperative.

1. Collaborative,Robots,(Cobots),2. MIG,Welding,(Metal,Inert,Gas,Welding),3. Welding,Automation,4. Human-Robot,Collaboration,(HRC,5. Industrial,Robotics

BLOG