- 产品描述

-

- Commodity name: RH 2006-W Industrial Robot: Precision Welding Powerhouse for Shelving & Scaffolding

- Chargeable Weight: 500

Unlock Unmatched Efficiency and Quality in Structural Welding with the RH 2006-W Robot and -E60-G4 Control Cabinet

Engineered for demanding fabrication environments, the RH 2006-W industrial robot paired with the advanced -E60-G4 Electrical Control Cabinet delivers exceptional performance, reliability, and safety, specifically excelling in high-volume shelf welding and complex scaffolding welding applications. This powerful combination is your key to maximizing productivity and achieving consistent, high-integrity welds on structural metal products.

Welding robots automate MIG, TIG, spot, and arc welding with precision, ensuring consistent weld quality, increased productivity, and enhanced safety in automotive, metalworking, and industrial applications.

Model

RH20-10-W

Arm form

Vertical multiple joints

Allowable Torque

Axis 4

24N.M

Degree of freedom

6 axis

Axis 5

24N.M

Maximum Payload

10kg

Axis 6

14N.M

Maximum Travel

Axis 1

Gound/upside down mounting -167~167° wall mounting -30~30°

Allowable moment of inertia

Axis 4

1.4 kg.m²

Axis 2

0~175°

Axis 5

1.4kg.m²

Axis 3

-80~150°

Axis 6

0.5kg.m²

Axis 4

-190~190°

Installation environment

Ambient temperature

0~45℃

Axis 5

-105~130°

Relative humidity

20~80%(no condensation

Axis 6

-210~210°

Vibration

Under 0.5 G

Maximum Speed

Axis 1

159°/s

Repeatability

±0.08mm

Axis 2

159°/s

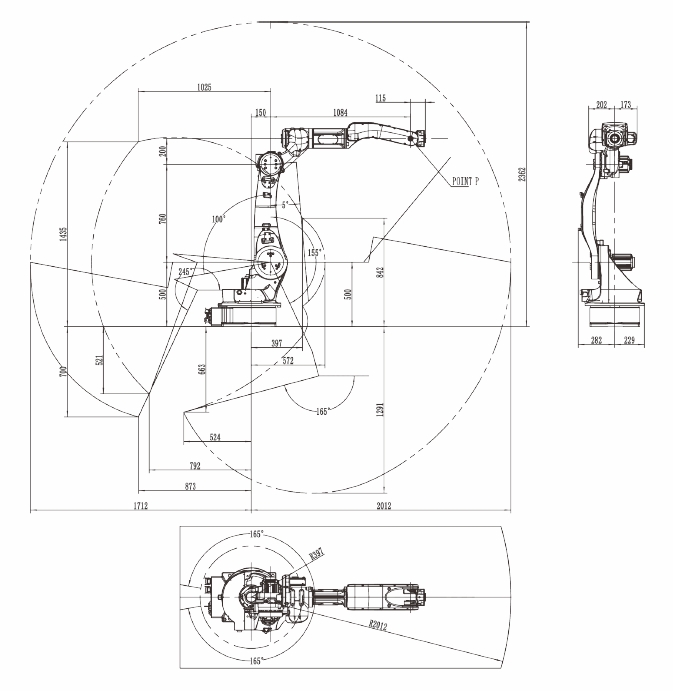

Maximum reaching distance

1920mm

Axis 3

169°/s

Robot body weight

288 kg

Axis 4

280°/s

Installation mode

Ground or upside down mounting

Axis 5

240°/s

Advantage features

Compact structure, High speed, High precision, High expansibility and easy operation

Axis 6

483°/s

Application

Welding

IP Level

Body IP 54, wrist IP 67

Why the RH 2006-W Dominates in Shelf and Scaffolding Welding:

1, Uncompromising Precision & Repeatability: Featuring serial precision (8 steps), the RH 2006-W ensures pinpoint accuracy weld after weld. This is critical for maintaining the dimensional tolerances required in pallet racking systems, storage shelves, and the intricate joints of industrial scaffolding, guaranteeing perfect fit and structural integrit

y.

y.

2, Blazing Cycle Times for High-Volume Output: Achieve remarkable throughput with cycle times as low as 2.5 seconds for optimized operations. Dominate production schedules for shelf manufacturing and meet the high-volume demands of scaffolding production efficiently.

3, Built for Industrial Rigor & Safety: The integrated safety circuit within the -E60-G4 cabinet and inherent robot safety protocols ensure operator protection and reliable operation within busy structural steel fabrication and metalworking environments. Focus on output with confidence.

4, Enhanced Power Stability & Noise Immunity: The -E60-G4 cabinet features a robust three-phase three-wire power filter and a three-phase 6/7-type servo isolation transformer (360V/350V). This ensures clean, stable power delivery, minimizing electrical noise interference that can disrupt sensitive welding processes – essential for consistent quality in metal welding.

Seamless Integration & Advanced Control:

- Distributed Real-time Control System (DRCS): Enables precise, synchronized motion control vital for complex welding paths common in scaffolding fabrication.

- Versatile Connectivity: USB Interface, TCP/IP Networking (IRAS Network Port), and support for external PLCs allow effortless integration into existing factory automation systems and welding automation cells.

- Comprehensive I/O: Ample digital I/O and provisions for temporary signal interfaces (application tracking) facilitate easy connection to welding power sources, positioners, sensors, and safety devices.

- User-Friendly Operation: Intuitive interfaces support multiple

operation modes, coordinate systems, and management operations, simplifying programming and operation even for intricate structural welding tasks.

operation modes, coordinate systems, and management operations, simplifying programming and operation even for intricate structural welding tasks.

Optimized for Welding Workflows: The system architecture prioritizes features crucial for welding:

- Precise path tracking capabilities.

- Support for external configuration and load commands.

- Robust interface design for reliable communication with welding equipment.

E60-G4 Control Cabinet: The Intelligent Powerhouse

- Robust Construction: Designed for harsh industrial environments (Dimensions: 55mm + 25mm vs 40mm profile).

- Integrated Safety: Built-in safety circuit prioritizes operator and equipment protection.

- Stable Power Conditioning: Three-phase power filter and isolation transformer ensure optimal performance for sensitive welding arcs.

- Future-Proof Connectivity: USB, Ethernet (TCP/IP), and extensive I/O options.

- Smart Control Foundation: Features enabling external PLC integration and sophisticated process control.

Dominate Your Structural Welding Market:

The RH 2006-W robot system is the ultimate solution for manufacturers specializing in:

- High-Speed Shelf Welding: Achieve rapid, consistent welds for pallet racks, storage systems, and industrial shelving.

- Complex Scaffolding Welding: Tackle intricate joints and geometries of tube and clip scaffolding, frame scaffolding, and system scaffolding with superior path accuracy and repeatability.

- Structural Steel Fabrication: Enhance productivity and quality in beam welding, column welding, and other structural welding applications.

- General Heavy-Duty Welding Automation: Where precision, speed, and reliability in metal joining are paramount.

Invest in the future of fabrication. The RH 2006-W and E60-G4 control cabinet deliver the speed, precision, reliability, and safety needed to excel in competitive shelf manufacturing and scaffolding production landscapes.

Keywords: RH 2006-W, Industrial Robot, Welding Robot, Robotic Welding, Shelf Welding, Scaffolding Welding, Pallet Rack Welding, Structural Welding, Metal Fabrication, Tube Welding, Structural Steel Welding, Automation, Manufacturing Automation, Welding Automation, -E60-G4 Control Cabinet, Robot Control Cabinet, High-Speed Welding, Precision Welding, Industrial Automation, Fabrication Equipment, Metal Joining, Manufacturing Efficiency.

Key words:- welding robot

- Industrial Robot

- Scaffolding Welding

- Pallet Rack Welding

- Structural Welding

- Metal Fabrication

products

Redefining Human-Robot Collaboration: Intelligent Power for Modern Logistics & Manufacturing

Flexible Laser Welding Solutions with Collaborative Robots