- 产品描述

-

- Commodity name: Mig welding Robot - Industrial Robot: Precision Automation for Structural Steel and Home Environment Manufacturing

- Chargeable Weight: 500

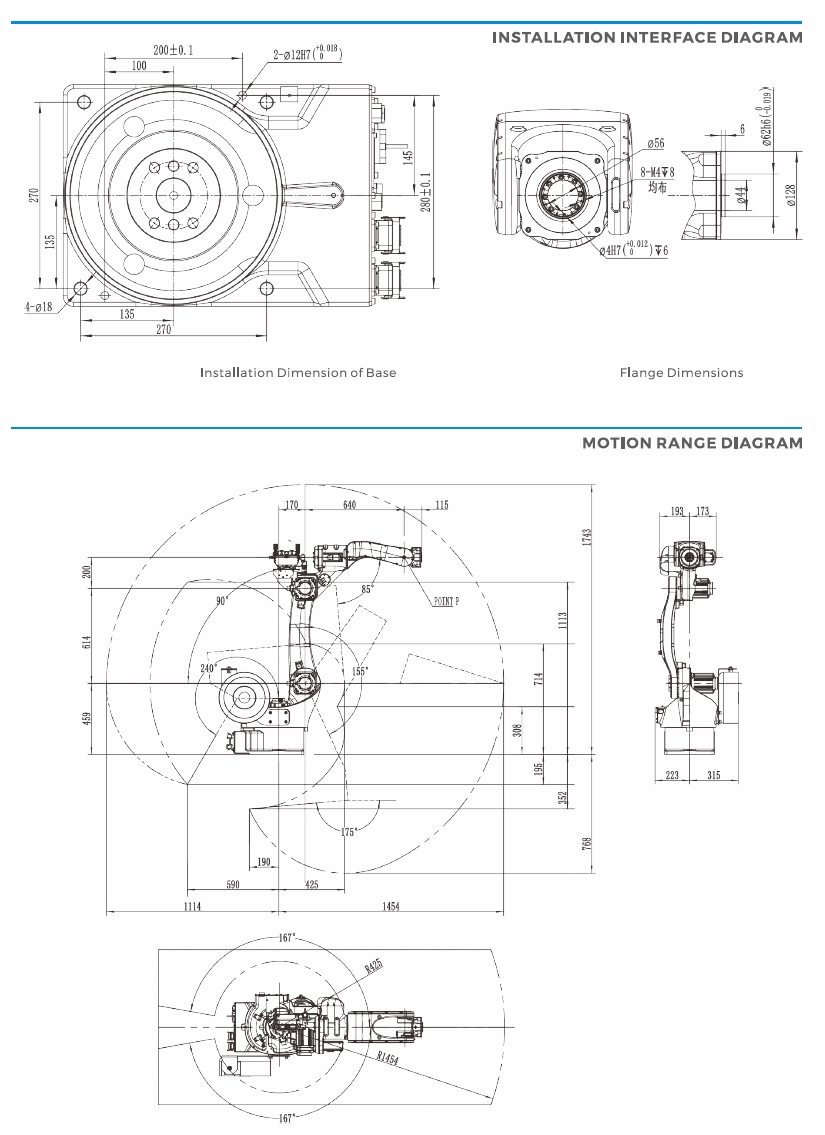

RH14-10-W Industrial Robot: Precision Automation for Structural Steel and Home Environment Manufacturing

Unlock unparalleled efficiency and quality in demanding fabrication environments with the RH14-10-W industrial robot. Engineered for robust performance and exceptional precision, this advanced automation solution excels in welding, cutting, spraying, and material handling applications, particularly within the structural steel fabrication and home appliance/electronics manufacturing sectors.

Model

RH-1410-W

Arm form

Vertical multiple joints

Allowable Torque

Axis 4

10N.M

Degree of freedom

6 axis

Axis 5

10N.M

Maximum Payload

10kg

Axis 6

3 N.M

Maximum Travel

Axis 1

Gound/upside down mounting -167~167° wall mounting -30~30°

Allowable moment of inertia

Axis 4

0.25kg.m²

Axis 2

0~175°

Axis 5

0.25kg.m²

Axis 3

-80~150°

Axis 6

0.05kg.m²

Axis 4

-190~190°

Repeatability

±0.08mm

Axis 5

-105~130°

Maximum reaching distance

1440mm

Axis 6

-210~210°

Robot body weight

170kg

Maximum Speed

Axis 1

169°/s

Installation mode

Ground or upside down mounting

Axis 2

169°/s

Installation environment

Ambient temperature

0~45℃

Axis 3

169°/s

Relative humidity

20~80%(no condensation

Axis 4

280°/s

Vibration

Under 0.5 G

Axis 5

240°/s

Others

Robot installation must be away from: flammable or corrosive liquids or gases, electrical sources of interference

Axis 6

520°/s

Advantage features

Compact structure, High speed, High precision, High expansibility and easy operation

IP Level

Body IP 54, wrist IP 67

Application

Welding

Core Technical Specifications & Features:

- High-Precision Motion: Achieves serial precision (8 steps) and rapid cycle times (e.g., 2.5 seconds placement), critical for high-volume production lines in home appliance assembly and intricate steel component welding.

- Advanced Welding Capabilities (Key Application Focus):

- Flexible Control: Supports both Analog control and Digital communication control for seamless integration with various welding power sources.

- Process Optimization: Features precise welding process speed adjustments and wire feed rate control (manual feed/withdraw) for optimal arc stability and bead quality on diverse materials, from thin home appliance chassis to thick structural steel beams.

- Flexible Control: Supports both Analog control and Digital communication control for seamless integration with various welding power sources.

-

- Enhanced Quality & Safety:

- Arc Break Detection & Recovery: Automatically detects wire breaks (An break detect), halts process, triggers alarms, and enables arc break point maintain for precise restart, minimizing scrap in critical structural welding.

- Pre-Gas/Post-Gas Control (Load-lag gas control): Ensures proper shielding gas coverage before and after the arc, crucial for clean welds in steel fabrication and preventing porosity.

- Simulation & Monitoring: Simulating welding function allows offline testing and validation. Real-time welding monitoring tracks current, voltage, and cycles for quality assurance and process optimization in both appliance production and heavy steel welding.

- Built-in Safety Circuit: Integral safety features protect personnel and equipment.

- Enhanced Quality & Safety:

Integrated Control System:

- -E60-G4 Electrical Cabinet: Provides robust power conditioning with a Three-phase three-wire power filter and Three-phase 6/7-type servo isolation transformer.

- Seamless Connectivity: Equipped with DRCS interface, IRAS network port (TCP/IP), USB Interface, Temporary signal interface, and Digital IQ Interface for comprehensive PLC integration (SERCO FIT PLC available), sensor communication, and external device control.

- User-Friendly Operation: Features management interfaces for Operations mode, Coordinate system, and Software package, facilitated by integrated user configuration tools.

- Robust Construction & Design:

- Power: Standard 200V/250V input.

- Dimensions (Cabinet Example): Approx. 550mm W x 250mm H x 50mm D (GND) - (Note: Robot arm dimensions typically larger).

- Built for Industry: Designed for reliable operation in challenging industrial environments.

Dominating Applications in Target Sectors:

- Structural Steel Fabrication:

- High-Strength Welding: Executes precise, consistent, and high-quality arc welding on beams, columns, trusses, and plates. Features like arc break recovery and robust welding monitoring are essential for ensuring the integrity of load-bearing structures.

- Efficient Cutting: Performs accurate plasma or oxy-fuel cutting of steel profiles and plates.

- Heavy-Duty Handling: Reliable loading and unloading of bulky steel components.

- Surface Preparation: Effective spraying for coatings, primers, or corrosion protection on large steel structures.

- Home Appliance & Electronics Manufacturing (3C Electronics Production):

- Precision Welding: Ideal for joining thin metals in home appliance frames, enclosures (ovens, washing machines, HVAC units), and electronics chassis. Digital control ensures clean, spatter-free joints.

- Delicate Component Handling: Gentle and accurate material handling for assembly of sensitive electronics and appliance sub-components.

- Consistent Spraying/Coating: Uniform application of paints, finishes, or protective coatings on appliance surfaces.

- Automated Assembly: Integrates into production lines for tasks like screw driving, part insertion, and sealing in smart home device manufacturing.

Why Choose the RH14-10-W?

- Proven in Critical Industries: Technology derived from systems applied in Automotive Industry and General Equipment Welding, adapted for the specific demands of structural steel and home environment manufacturing.

- Optimized for Welding: Comprehensive suite of welding-specific functions ensures superior results and process control.

- Reliable & Safe: Industrial-grade construction, integrated safety systems, and stable power conditioning guarantee uptime.

- Future-Proof Connectivity: Modern interfaces enable easy integration into Industry 4.0 environments and existing factory networks.

- Enhanced Productivity: High speed, precision, and automated recovery features maximize output and minimize downtime.

Elevate your structural steel fabrication or home appliance production line with the power, precision, and reliability of the RH14-10-W Industrial Robot. Contact us today to discover how this solution can optimize your manufacturing processes.

Key words:- welding robot

products

Redefining Human-Robot Collaboration: Intelligent Power for Modern Logistics & Manufacturing

Flexible Laser Welding Solutions with Collaborative Robots